Welcome to Borrett !

- More Categories

- Less Categories

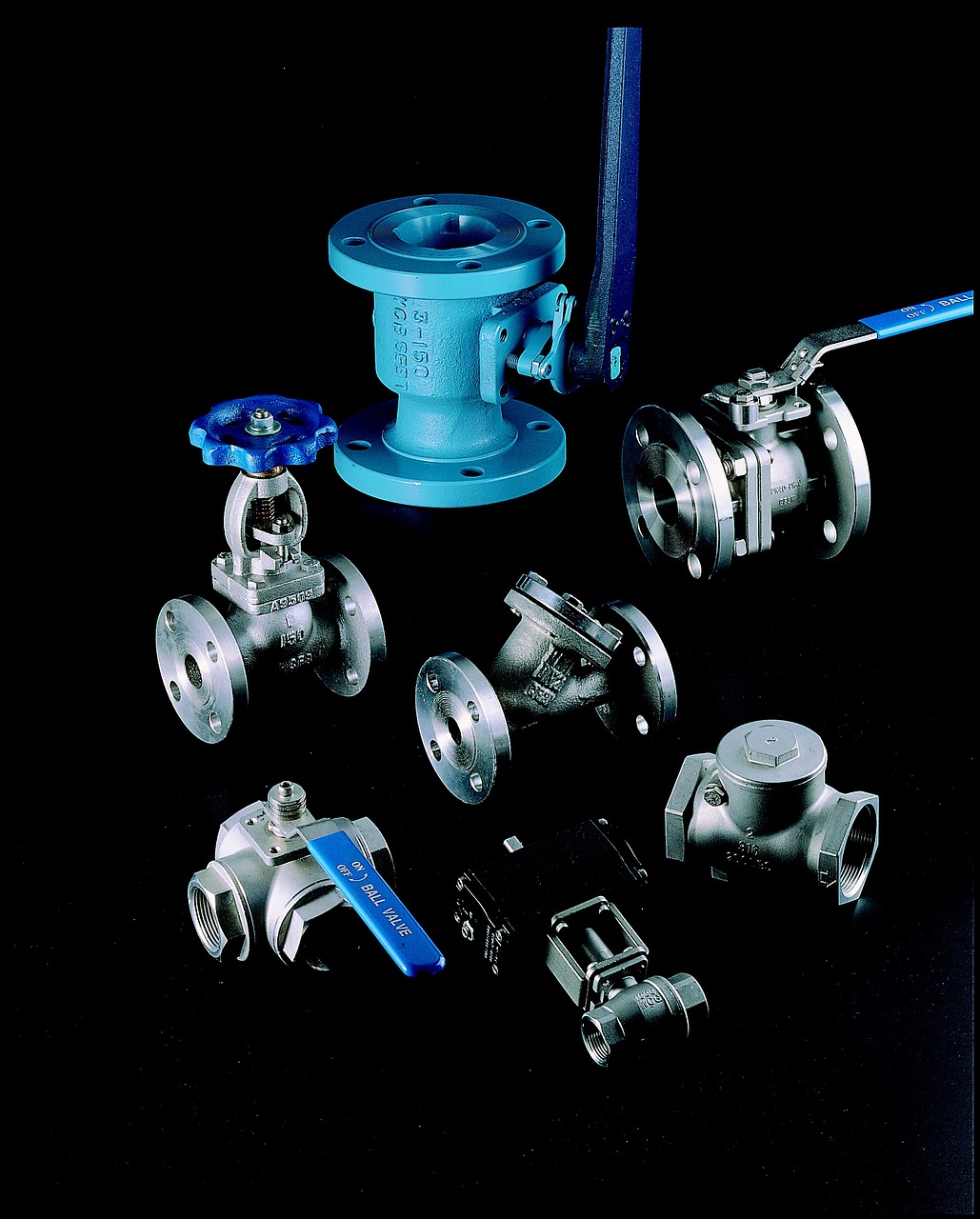

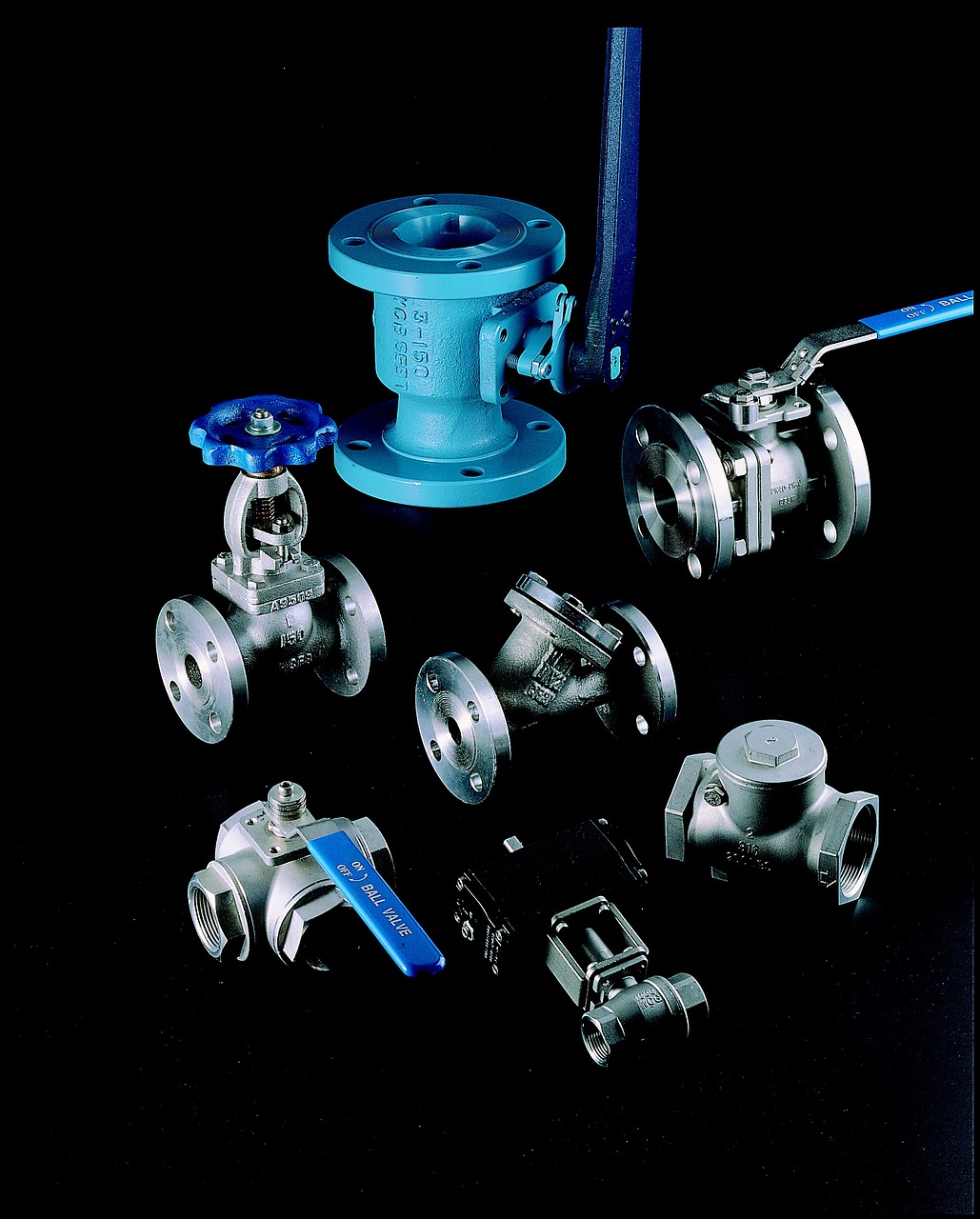

As a buyer comparing different control solutions, you need an Intelligent Valve that delivers precise flow control, reliable feedback, and long service life in harsh process environments. Our China intelligent valve factory designs custom intelligent control valves with smart positioners, diagnostic functions, and flexible communication options, helping you balance performance, life-cycle cost, and automation integration across new projects and retrofit jobs.

Every Intelligent Valve is built with high-grade metals, refined sealing technology, and CNC-machined trims to ensure tight shut-off and stable Cv. Modular actuators, field-replaceable accessories, and OEM customization options allow you to match pressure class, temperature rating, and end connections to your P&ID. Compared with conventional valves, our intelligent valve solutions reduce unplanned downtime through continuous monitoring and early-warning diagnostics, giving plant engineers clearer data for preventive maintenance.

From clean media to slurry, steam, and corrosive chemicals, our OEM Intelligent Valve for sale range is engineered for complex conditions in power, mining, chemical, and water treatment plants. When comparing designs, buyers can also review our ball valve wholesale options, ceramic valve solutions, plug valves, regulating valves, knife gate valves and butterfly valves to build a complete, consistent control package.

As a professional Intelligent Valve exporter and trader, we support EPC contractors and distributors with engineering files, datasheets, and training through our application solutions, warranty & training programs, technical downloads, FAQ and valve video tutorials. Our valve knowledge hub shares social stories, case studies, and industry news that you can repurpose for your own marketing channels.

Backed by a modern China intelligent valve factory and strict quality culture, we offer flexible flow control combinations with pumps, fast OEM sampling, and stable wholesale supply for global partners. Learn more about our company background and corporate values on the company introduction, and contact our team via contact page to discuss custom intelligent valve projects or long-term distributor cooperation.

The Intelligent Valve represents the new generation of automated flow control solutions. As buyers compare advanced process systems, they value valves that merge digital intelligence with mechanical durability. Our China Intelligent Valve Factory integrates precision sensors, positioners, and feedback modules into each product to deliver accurate, responsive, and efficient control. Built under strict ISO and CE standards, these smart valves adapt dynamically to pressure, temperature, and flow variations, ensuring long-term stability in industrial environments.

From a manufacturing standpoint, each custom intelligent valve is produced using CNC machining centers, precision polishing, and pressure-tested assemblies. Core materials include stainless steel, alloy steel, duplex, and ceramic-reinforced sealing seats to resist corrosion, cavitation, and high-cycle wear. These attributes make our valves ideal for power generation, chemical processing, oil & gas, water treatment, and pulp & paper sectors, where reliability and automation are critical. Buyers evaluating performance will find our smart control systems respond faster, require less maintenance, and integrate seamlessly with existing PLC or DCS platforms.

Each OEM Intelligent Valve from our China factory undergoes advanced flow simulation and endurance testing before shipment. The intelligent actuator combines pneumatic or electric drive with embedded sensors that continuously measure stem movement and torque. Through fieldbus or 4-20mA signal communication, engineers can monitor valve health in real time. Compared to conventional globe or ball valves, this smart valve design reduces leakage risk, enables predictive maintenance, and supports precise throttling in critical service conditions.

For buyers comparing automation equipment, our Intelligent Valve Manufacturer offers a complete design-to-delivery workflow. We provide CAD drawings, pressure-temperature curves, and lifecycle analytics, empowering global OEM partners to integrate these valves into their own systems. This not only enhances operational transparency but also aligns with the shift toward Industry 4.0 and smart plant management. When combined with data analytics, our intelligent control valves create measurable efficiency gains across diverse industrial networks.

As a leading intelligent valve exporter and trader in China, we offer wholesale pricing, flexible MOQ, and tailored branding for distributors and EPC contractors. Our export-ready designs comply with ASME, API, and DIN standards, ensuring compatibility across international markets. Buyers can also explore related flow control options including Ball Valves, Ceramic Valves, Plug Valves, Regulating Valves, Knife Gate Valves, and Butterfly Valves — creating integrated smart fluid networks.

We also provide full technical documentation through our solution center, downloads, and FAQ resources, ensuring every buyer can make informed comparisons between performance metrics, valve response curves, and automation integration levels. Our video training library and warranty programs further support clients post-installation, reinforcing our long-term partnership model.

When compared to standard valves, the Intelligent Control Valve stands out in four dimensions: accuracy, adaptability, diagnostics, and energy efficiency. By automatically adjusting to differential pressure and process changes, it minimizes human intervention and reduces overall operating cost. For buyers comparing suppliers, our OEM solutions combine strong mechanical integrity with electronic control intelligence—bridging the gap between mechanical reliability and digital responsiveness. This is a crucial advantage for modern industries focusing on sustainability and process optimization.

The working environment of an intelligent valve typically includes extreme pressure, temperature fluctuation, or corrosive fluids. In refineries, for example, the valve communicates with control systems to modulate feed flow precisely; in water treatment plants, it ensures consistent dosing and prevents system shock. Thanks to its adaptive control logic, each valve delivers smooth actuation, reducing noise, vibration, and wear—ultimately extending service life and ROI for end-users.

We invite partners seeking Intelligent Valve OEM service or wholesale collaboration to explore our advanced China factory. Our production capabilities include automated machining, robotic welding, digital quality tracking, and assembly lines compliant with API 6D and ISO 9001. Whether for municipal, petrochemical, or mining sectors, our engineering team tailors custom configurations to meet complex process demands. Buyers can also combine our valves with pneumatic diaphragm pumps for complete automation packages.

Explore more insights at our Valve Knowledge Hub, review company background in the Company Introduction, and learn about our Corporate Culture and Development History. For inquiries or project quotations, please visit our Contact Page.