Custom Butterfly Valves Quality Control & Production Assurance

China Butterfly Valves Factory / Manufacturer / Supplier / OEM for Sale

As a QA inspector responsible for ensuring the reliability of every custom butterfly valve leaving our China factory, quality begins with precision casting, machining, and inspection of the valve body, disc, and seat. Each unit passes dimensional verification, pressure testing, and torque measurement before packaging. The production process combines automated CNC systems with skilled manual checks, ensuring uniformity in concentricity, sealing surfaces, and coating adhesion. By maintaining a robust OEM quality framework, our Butterfly Valves Manufacturer in China consistently meets global performance standards for HVAC, water treatment, fire control, and industrial automation.

Butterfly valves are defined by their simple yet efficient rotary motion mechanism, where the circular disc pivots to control flow. QA inspectors validate each disc’s smooth rotation under low torque and its precise shutoff integrity across pressure ratings. The valve’s attributes include light structure, compact installation, high flow capacity, and stable performance under varying fluid conditions. Coatings and elastomer selections are verified for compatibility with potable water, seawater, chemical, or air handling systems. Each OEM butterfly valve undergoes cyclic endurance testing to confirm service life and repeatability.

Trader / Exporter / Wholesale OEM Inspection Perspective

From the QA inspector’s viewpoint, exporting butterfly valves requires more than performance—it demands traceability and documentation. Each lot is coded and logged in our China OEM butterfly valve quality system, enabling traders and global distributors to access conformity certificates, material reports, and hydrostatic testing data. This ensures full compliance for wholesale and project deliveries across residential, commercial, and municipal infrastructures. During third-party audits, inspectors crosscheck production records and calibration certificates to uphold ISO and CE compliance.

The working environment for butterfly valves covers HVAC pipelines, ventilation systems, fire suppression networks, and water supply grids. QA inspection teams simulate these service conditions during testing—evaluating the sealing under temperature swings, pressure shocks, and vibration exposure. For OEM residential applications, emphasis is placed on noise control, air cleanliness, and smooth actuation for breathable living spaces. Butterfly valves contribute to energy efficiency by minimizing head loss and supporting precise flow regulation in smart-home water and air systems.

China Custom Butterfly Valve OEM Service & Advanced Production

Inside our Butterfly Valve Factory in China, production is organized around lean manufacturing cells. Material traceability starts from certified foundries, and non-destructive tests—like ultrasonic inspection and magnetic particle examination—ensure internal integrity. QA inspectors monitor each batch of epoxy coatings for film thickness and curing temperature to guarantee corrosion resistance. Final assembly is performed in clean areas to prevent debris contamination on seats and stems. Every butterfly valve passes a hydrostatic test at 1.5× nominal pressure and a seat leakage test according to API 598 before shipment.

Our OEM manufacturing process supports customized designs including wafer, lug, flanged, and triple-offset butterfly valves. QA inspectors oversee process audits during pattern design, foundry heat treatment, and precision machining. All gauges and pressure instruments are regularly calibrated in compliance with ISO 9001 and IATF quality systems. Through continuous improvement, our China OEM production line maintains repeatability, achieving ±0.02 mm tolerance consistency across the sealing diameter—critical for long-term reliability in automation networks and HVAC systems.

Wholesale Butterfly Valves QA Partnership

We collaborate closely with global wholesale distributors and EPC contractors to integrate QA traceability from production to installation. Detailed inspection reports, assembly photos, and final test records accompany every shipment, simplifying import certification. The inspector ensures conformity to customer specifications, verifying seat hardness, torque curves, and dimensional drawings. Our internal system links inspection data with order IDs for instant recall—strengthening transparency for international partners dealing in custom butterfly valves OEM service.

To further enhance user confidence, customers can access detailed technical references and performance videos through our Valve Knowledge Hub, learn more about Company Introduction, or explore Warranty & Training services to ensure proper valve maintenance. Our Download Center provides datasheets, while additional technical assistance is available through our Contact Page.

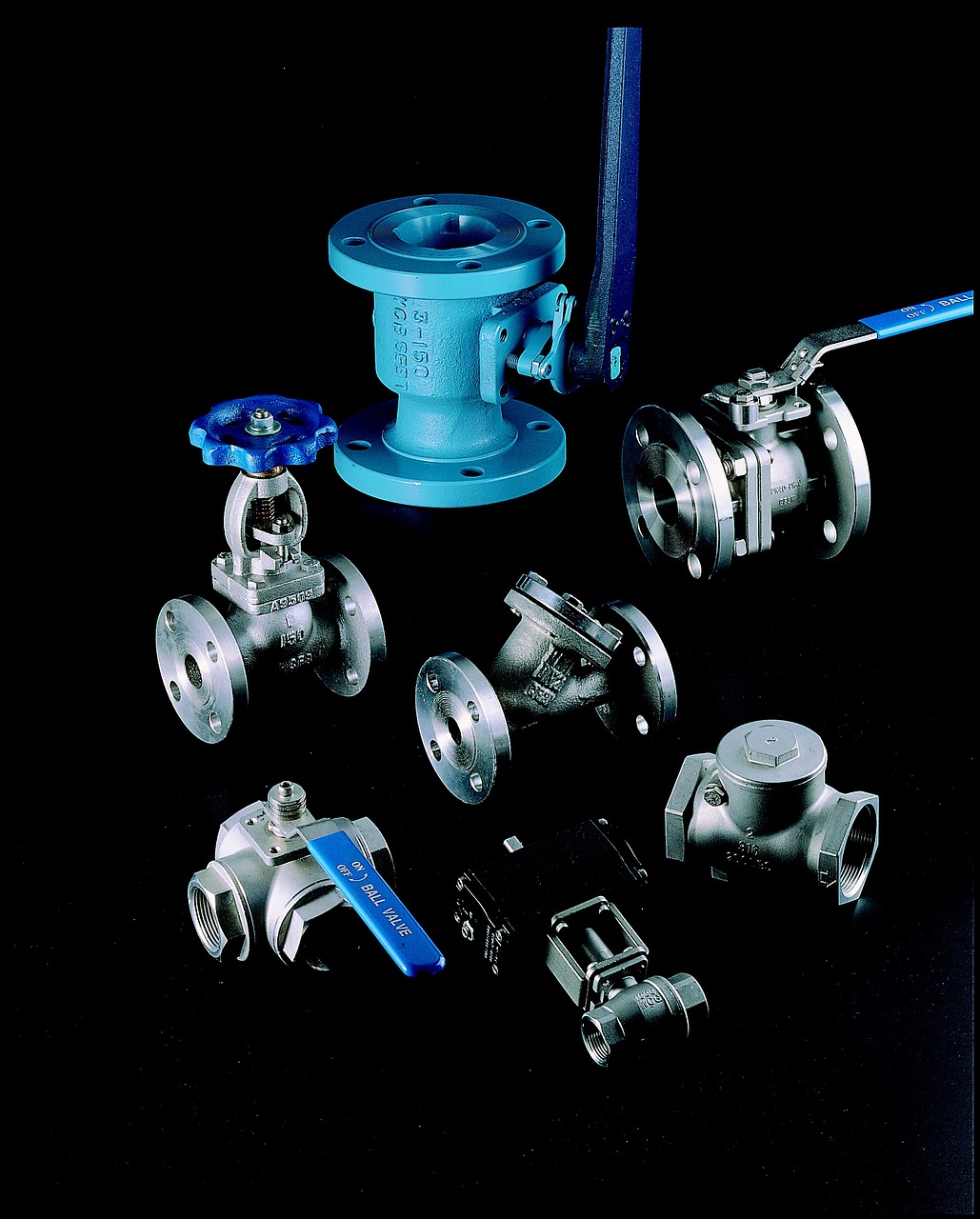

QA inspectors regularly visit assembly lines of other products, including Ball Valves, Ceramic Valves, Plug Valves, Regulating Valves, Knife Gate Valves, and Pneumatic Diaphragm Pumps, ensuring consistent production standards across all valve families. This cross-verification system gives clients confidence that their butterfly valves perform seamlessly when integrated with other control and isolation equipment in complex piping networks.

As a QA professional, I can confirm that each custom butterfly valve undergoes multi-layer inspection, aligning with the engineering philosophy of reliability, sustainability, and customer trust. Through rigorous verification, responsive OEM services, and transparent export compliance, our Butterfly Valves Manufacturer in China ensures every product not only meets but exceeds the global benchmark for fluid control. Choose our certified OEM butterfly valves to safeguard your systems with precision, durability, and long-term performance assurance.