Custom Pipeline Fittings / Integrated Industrial Pipeline Connection Solutions

China pipeline fittings factory, manufacturer, supplier, OEM partner & wholesale exporter for global industrial projects.

Factory Direct Pipeline Fittings China OEM Pipeline Fittings Manufacturer Industrial Pipeline Fittings Supplier for Sale Custom Pipeline Fittings OEM Service

Manager Responsible · Production & Quality of Pipeline Fittings

Custom Pipeline Fittings Factory & OEM Manufacturer in China

As a manager responsible for safety, budgets and uptime, you need pipeline fittings that are produced with repeatable quality and full transparency. In our China pipeline fittings factory, every elbow, tee, reducer, flange and coupling is manufactured under controlled processes that you can confidently present to your internal stakeholders and end users. From raw material selection to final packing, we apply traceable inspection steps, welding procedures and heat treatment parameters suited to high-pressure and corrosive service environments. This allows you to specify OEM pipeline fittings for oil & gas, chemical processing, water treatment and power generation projects without compromising on compliance or lifecycle cost.

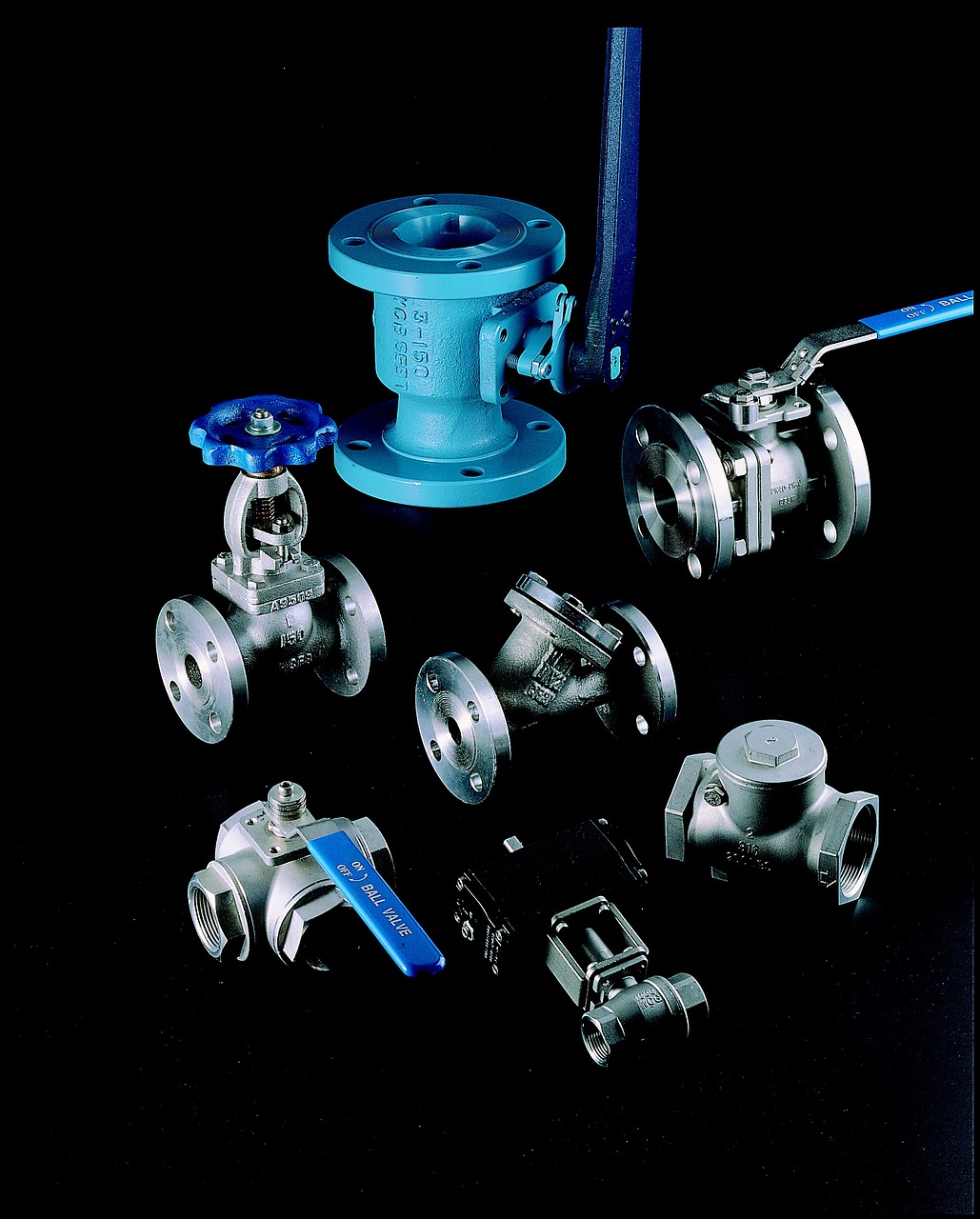

Our production range covers carbon steel, stainless steel and alloy-steel pipeline fittings engineered according to international standards, with options to match your preferred ball valve, ceramic valve, plug valve or regulating valve specifications. Dimensional accuracy and surface finish are monitored so that the pipeline fittings align smoothly with globe valve, knife gate valve and butterfly valves, helping your installation team avoid rework and schedule delays.

For managers evaluating suppliers, we provide clear documentation of manufacturing capability, test plans, and warranty conditions through our engineering solution center and warranty & training service. This makes it easier for you to justify supplier selection, standardize on one OEM pipeline fittings manufacturer, and reduce the complexity of your approved vendor list while keeping risk under control.

Attributes · Materials · Operating Conditions

Custom Pipeline Fittings for Demanding Industrial Service Environments

Modern custom pipeline fittings must combine mechanical strength, sealing performance and corrosion resistance to operate reliably in diverse environments. Our OEM pipeline fittings portfolio includes butt-welded, socket-welded and threaded connections for high-pressure transmission lines, low-temperature utility systems, abrasive slurry transport and aggressive chemical media. Wall thickness, bevel geometry and lining options are optimized so you can match fittings to the duty conditions of your valves, pumps and instrumentation, including pneumatic diaphragm pumps working in dosing and transfer applications.

In refineries and petrochemical plants, pipeline fittings are exposed to temperature cycles, vibration and sometimes sour service. Our China pipeline fittings OEM service can deliver material certificates, non-destructive testing reports and hydrostatic pressure test results that help you demonstrate compliance during audits. For power and energy projects, long-radius bends and reinforced branch fittings help maintain flow efficiency and reduce local stress, supporting long-term reliability of your pipeline network. In municipal water treatment and desalination, corrosion-resistant alloys and protective coatings extend service life and support sustainable asset management strategies.

As a manager responsible for project outcomes, you gain confidence from a single supplier that understands the interaction between pipeline fittings, control valves, safety valves and instrumentation. Our engineering team works with your designers to propose bill-of-materials that balance safety margins and total installed cost, so that your pipeline fittings selection supports both capital expenditure targets and maintenance budgets across the complete life cycle.

Trader · Exporter · Wholesale Pipeline Fittings

Global Trader, Exporter & Wholesale Partner for Pipeline Fittings

In addition to manufacturing, we act as a pipeline fittings trader, exporter and wholesale supplier, integrating sourcing, consolidation and export documentation for your regional warehouses and distribution channels. If you manage a multi-country supply chain, our China wholesale pipeline fittings service allows you to combine fittings with ball valves for sale, butterfly valves for HVAC and water and other flow-control equipment in one shipment. This reduces freight cost per item and simplifies customs procedures.

Our wholesale pipeline fittings OEM service can include customized packaging, neutral or branded labels, barcodes and palletization tailored to your warehouse system. As an exporter, we provide clear markings and country-of-origin details, helping your finance and logistics teams manage duties and local regulatory requirements. For trading companies and large distributors, stable lead times and forecast-based production planning support your inventory strategy, ensuring that pipeline fittings are available when your customers need them, without tying up excessive working capital.

Because we handle both OEM manufacturing and international trading, your organization benefits from a single point of responsibility. When you coordinate projects that include complex valve packages – such as knife gate valves for slurry, ceramic valves for abrasion and regulating valves for process control – we can match the pipeline fittings to each duty and deliver them in unified project kits. This makes life easier for site supervisors and installation contractors, and it helps you as the responsible manager deliver projects on time and to specification.

Manager Responsible · Advantages & Support

Management-Level Advantages of Partnering with a Custom Pipeline Fittings OEM Supplier

Choosing the right pipeline fittings OEM manufacturer is not only a technical decision; it is a strategic management choice. By working with a China custom pipeline fittings factory that integrates design support, production, wholesale distribution and after-sales service, you reduce interface risk and communication effort across your projects. Fewer vendors, unified technical standards and consistent documentation free your team to focus on engineering optimization instead of daily expediting and troubleshooting.

For managers responsible for ESG and corporate culture, our approach supports long-term relationships built on transparency. You can introduce our manufacturing environment, testing capabilities and training programs to your colleagues and customers via the corporate culture and development history sections on our website. This content, along with videos and knowledge articles, can be shared on your social media channels to strengthen your brand’s technical image when promoting custom pipeline fittings, valve packages and turnkey pipeline solutions.

Our support team provides quick feedback on inquiries, drawings and specification changes, minimizing the risk of delays when projects move from FEED to execution. When new plants or system upgrades require integrated solutions, we help you align pipeline fittings with actuated valves, pumps and accessories, making your final offer to end users more competitive. In short, partnering with a dedicated custom pipeline fittings OEM service helps managers meet performance targets, protect budgets and improve customer satisfaction across multiple projects and regions.